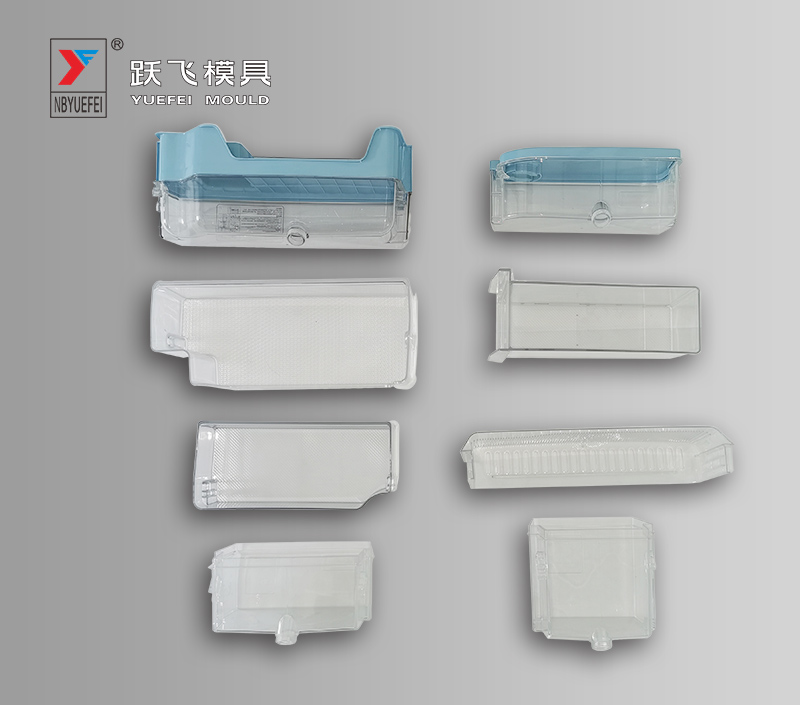

To be honest, there are still many precautions about mold manufacturing. For example, when designing a cold stamping die, the information needs to include product drawings, samples, design tasks and reference drawings. Need to pay attention to see if the product view provided by the customer is complete, what kind of requirements are there in terms of technical requirements, and whether there are any special requirements. It is important to understand the requirements of customers thoroughly, whether it is trial production, mass production, or mass production when starting production. This question is very important. Understand the material properties, dimensions and supply methods of the parts, and especially determine the reasonable gaps for punching and the feeding methods for punching.

What is the mold drying process

The mold patterning process is actually the effect of making a pattern on the plastic or plastic product mold, because today's era is always in pursuit of exquisiteness, and ordinary pure color crafts can no longer satisfy people's psychology. So at this time the tanning process is produced. In fact, there are two processing methods for this tanning process. One is to use a potion to make the tanning process appear in front of you, and the other is to use a laser to There is a sunstroke. Next, let’s talk about the tanning process of the syrup. After removing the oil and washing the film, the mucous membrane is required, and then chemical inspection and surface treatment are performed. At this time, printing can be done. There are also several types of patterns in the printing process, and printing is done. After the treatment, it can be trimmed and then chemically etched.

In fact, this step is to use the potion to make the pattern deeper, and then do the surface treatment, don't forget the rust removal step, and just pack it. It can be said that this kind of chemical syrup is very cumbersome and not environmentally friendly. Even the stability is very poor, and the surface looks rough. In fact, no matter which one is compared, the tanning process of this potion is not as good as the laser tanning process.

www.yfmould.com

English

English 简体中文

简体中文 Español

Español Deutsche

Deutsche