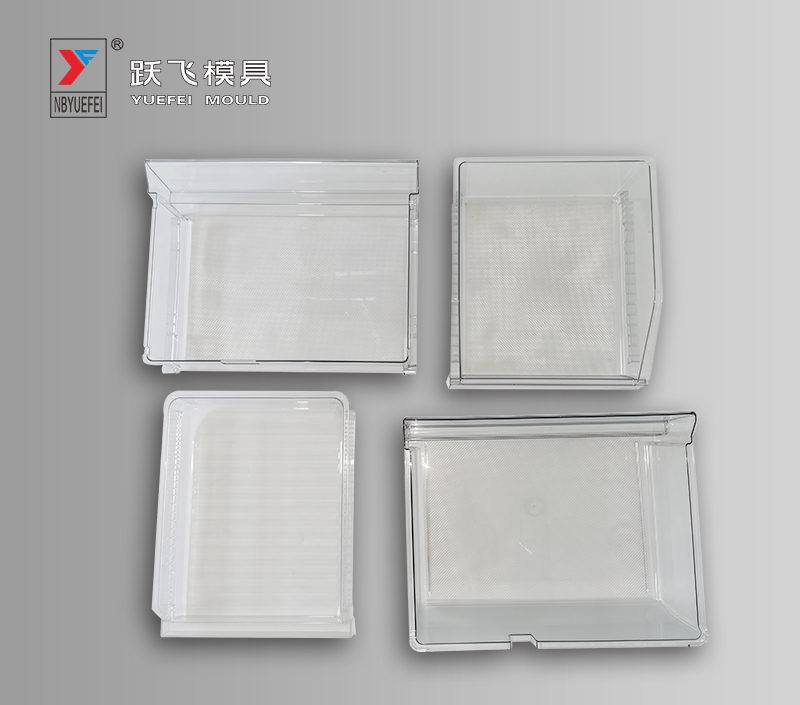

I believe people who know a little about mold design will know that it is particularly troublesome to design a set of molds. First of all, if we need to design a plastic mold, we need to accept the task book. Only after accepting the task book can we know what prompts there are in the task book, and the designer can better follow these prompts to design. Collecting, analyzing and digesting the original data, it usually takes some time to complete this step, because the collection and sorting of related production design, molding process, molding equipment, mechanical processing, and special processing data are only needed in the design mode. Too much trouble.

After the mold is designed, it is necessary to determine the molding method of the mold. This step is particularly important. What we need is the design step of the plastic mold. Therefore, the plastic mold usually adopts the direct pressure method, the casting method or the injection method. . The molding equipment is selected. When choosing this, you need to choose according to the performance and specifications of the molding equipment. If the equipment is selected correctly, the mold will be better. The design steps of the plastic mold need to determine the specific structural plan. Organize the data and archive it. After the mold test, it needs to be wiped well, then coated with anti-rust oil, and sent to the storage place for storage.

What mold designers need to master

After our understanding, we found that a qualified mold designer needs to master mechanical drawing. If you have learned it, it would be better, but if you haven't learned it, you can buy books to learn. Designers also need to have a certain understanding of the processing technology, because only by understanding the processing technology can they take this part into consideration while designing the mold. In addition, a qualified mold designer needs to master theoretical knowledge of plastics, injection molding machines, products, etc. In fact, this theoretical knowledge is relatively simple, and we need to read more books to understand more, and more in daily operations. Pay attention, you can see the accumulation of the world, and gradually will.

There are many things that designers need to master in the design steps of plastic molds. For example, mold structure is the core thing that designers need to master. Only when you understand the mold structure can you design a complete mold with your own information. . In addition, if a designer wants to design a mold, he can't do without software operation, so he must be proficient and proficient in software operation ability. Classic drawing software like CAD is still very necessary to learn, and it is said that designers have very strict requirements for shortcut keys, and they can even switch shortcut keys with only gestures.

www.yfmould.com

English

English 简体中文

简体中文 Español

Español Deutsche

Deutsche