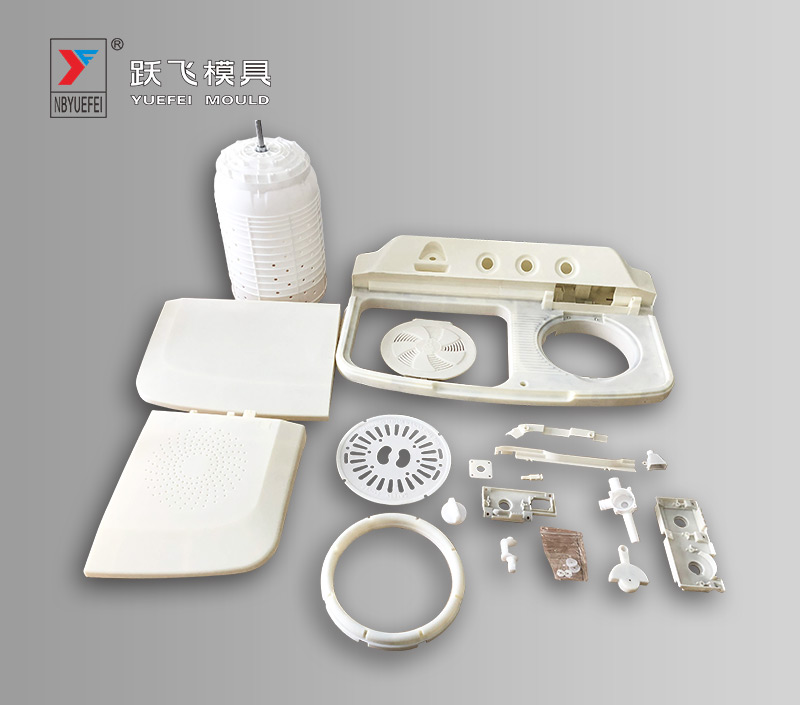

Words that we don't usually hear in daily life are thermoformed. In fact, the food containers, plastic trays, auto parts, home appliances, etc. that can be found in supermarkets and convenience stores, plastic things around our lives are made by thermoforming.

Plastics are softened after heating, and then hardened after cooling, which fully exerts this characteristic.

1. First heat the plastic sheet

2. After the sheet is softened, cover the sheet on the mold

3. Attract the air in the mold and become a vacuum state

4. Paste the softened plastic sheet on the mold, and then shape it into the shape of the product.

At this time, using positive pressure to remove excess air in the mold, it is possible to form complex products, which is called "pressure forming".

Air pressure forming

The heating methods of thermoforming include radiation heating, contact heating and hot air heating. Asano Research Institute uses radiant heating and contact heating. Radiant heating is a method in which infrared rays emitted by a heater heat the sheet. Suitable for food containers, industrial trays, home appliances, auto parts, etc. Contact heating is a method of directly heating the sheet in contact with the hot plate. The mold and the hot plate clamp the sheet to fix and heat the sheet, which is suitable for high-precision printed materials such as sheets that shrink greatly after heating, and automobile parts.

www.yfmould.com

English

English 简体中文

简体中文 Español

Español Deutsche

Deutsche