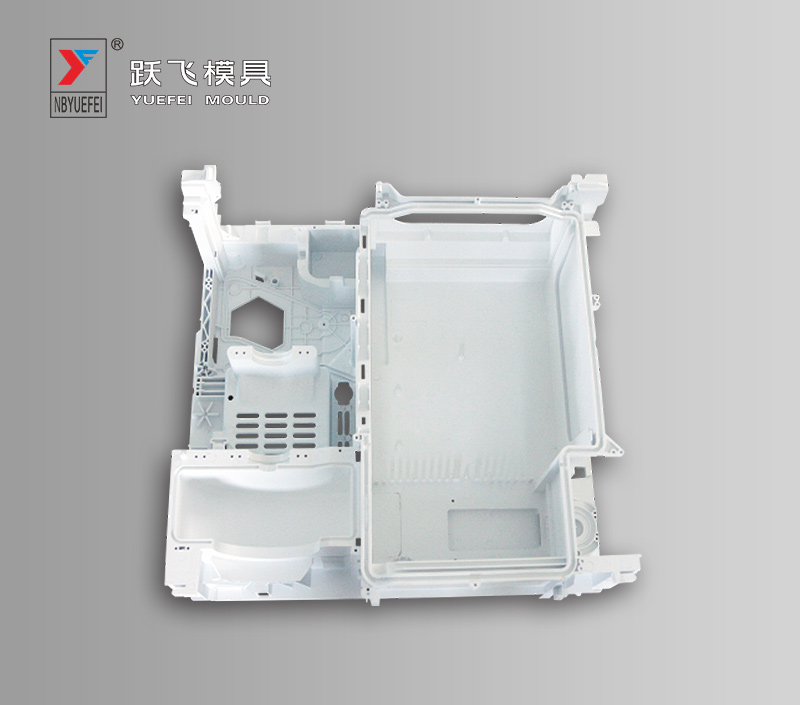

The quality of metal die-casting molds includes the following aspects: (1) Product quality: product dimensional stability, compliance, product surface finish, product material utilization, etc.; (2) Service life: on the premise of ensuring product quality, the mold The number of work cycles that can be completed or the number of parts produced; (3) The use and maintenance of the mold: whether it is the most convenient to use, easy to demold, and the production auxiliary time as short as possible; ⑷ maintenance cost, maintenance periodicity, etc.

The basic way to improve mold quality: mold design is the most important step to improve mold quality. Many factors need to be considered, including the selection of mold materials, the usability and safety of mold structure, the machinability of mold parts and the mold Convenience of maintenance, these should be considered as comprehensive as possible at the beginning of the design. The mold manufacturing process is also an important part of ensuring the quality of the mold. The processing method and processing accuracy in the mold manufacturing process will also affect the service life of the mold. The accuracy of each part directly affects the overall assembly of the mold. In addition to the accuracy of the equipment itself, it is necessary to improve the processing method of the parts and improve the technical level of the fitter in the mold grinding and matching process to improve the processing accuracy of the mold parts . The surface of the main forming parts of the mold is strengthened to improve the surface wear resistance of the mold parts, so as to better improve the quality of the mold. The correct use and maintenance of the mold is also a major factor in improving the quality of the mold. For example: mold installation and debugging methods should be appropriate, in the case of hot runners, the power supply wiring must be correct, the cooling water circuit must meet the design requirements, and the parameters of the injection molding machine, die casting machine, and press in the mold production must meet the design requirements and many more. When using the mold correctly, it is necessary to perform regular maintenance on the mold. The guide posts, guide sleeves and other parts of the mold should be filled with lubricating oil frequently. For forging molds, plastic molds, die-casting molds, etc. Lubricant or mold release agent should be sprayed on the surface of the molded part before molding.

With the development of society, the quality of molds has attracted more and more attention. With the strengthening of the design and manufacturing of molds and the realization of new mold technologies, the quality of metal die-casting molds has received more and more attention. Quality is a frequently said topic, and quality is improving with the improvement of mold technology.

www.yfmould.com

English

English 简体中文

简体中文 Español

Español Deutsche

Deutsche