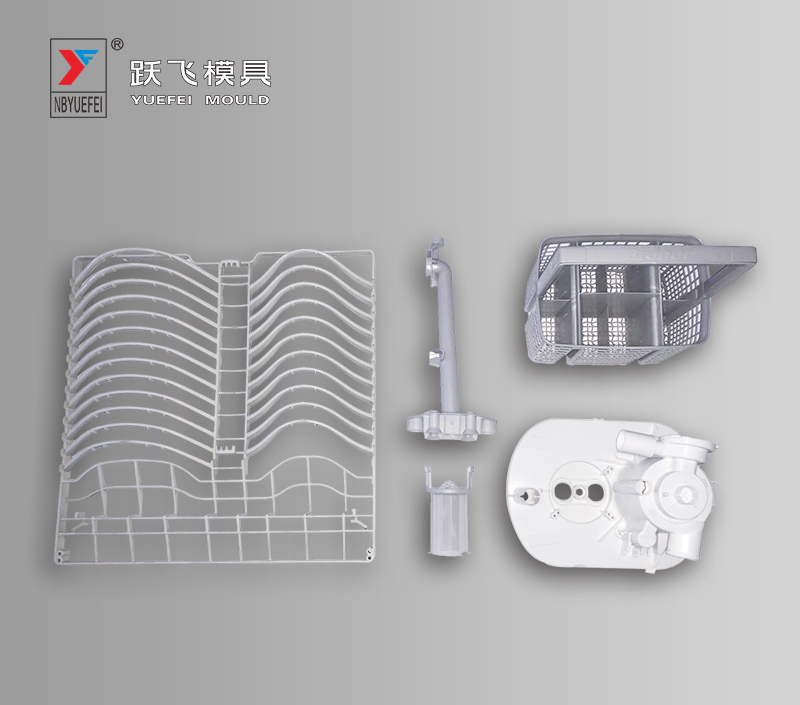

Mechanical molds are tools used to shape objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material. In the forming process of punching, forming stamping, die forging, cold heading, extrusion, powder metallurgy parts pressing, pressure casting, and compression molding or injection molding of engineering plastics, rubber, ceramics and other products, it can be used under the action of external force. The blank becomes a tool for a workpiece with a specific shape and size.

The mold has a specific contour or inner cavity shape, and the contour shape with a cutting edge can separate the blank according to the contour shape, that is, punching. The shape of the inner cavity can be used to obtain the corresponding three-dimensional shape of the blank. The mold is generally divided into two parts: a movable mold and a fixed mold, or a convex mold and a concave mold. They can be separated or combined. The blank is loaded or the part is taken out when separating, and the part is separated or formed from the blank when closed. In the process of blanking, forming, stamping, die forging, cold heading, pressing and compression molding, the external force required for separation or forming is applied to the blank through the die.

The mold has multiple complex cavities and poor working conditions. The red steel above 1000°C deforms and flows and washes in the mold cavity. The mold has to withstand the high-speed impact of the forging hammer or the pressure of a heavy load. It is often used during use. It is in a state of rapid cold, rapid heat and alternating hot and cold. The mold material should have high strength, toughness and wear resistance, and must have high temperature strength and hardness during hot forging, and undergo a strengthening and toughening heat treatment.

The application of molds is extremely wide. Mass production of electromechanical products, such as automobiles, bicycles, sewing machines, cameras, motors, electrical appliances, meters, etc., as well as the manufacture of household appliances, use a large number of molds. Molds are basically produced in a single piece, with complex shapes and high requirements for structural strength, rigidity, surface hardness, surface roughness and processing accuracy, so mold production requires a high level of technology. The timely supply of molds and their quality directly affect product quality, cost and new product development. The development level of mold production is one of the important signs of the level of mechanical manufacturing.

www.yfmould.com

English

English 简体中文

简体中文 Español

Español Deutsche

Deutsche