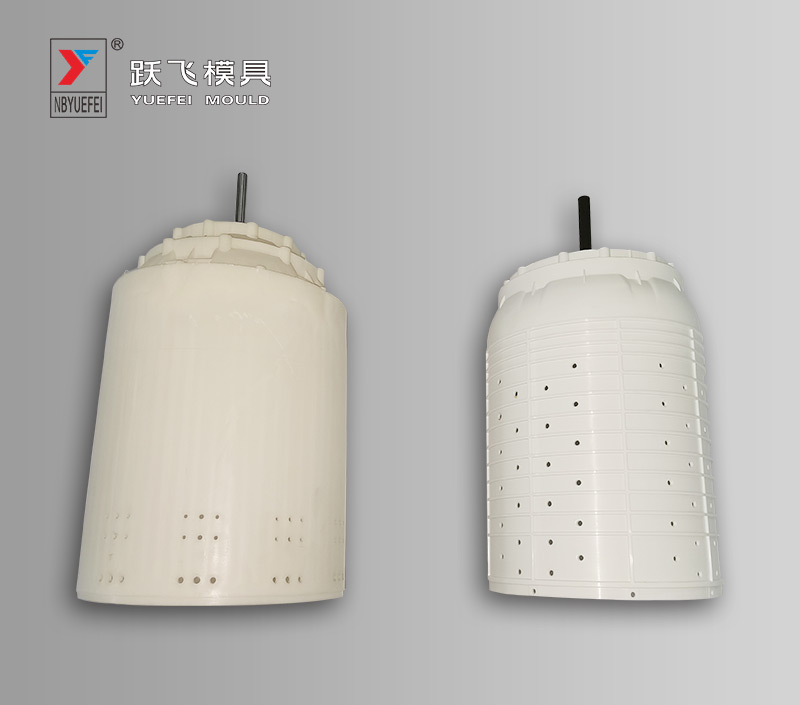

Automobile parts molds require much higher processing equipment than traditional injection molding. Generally, there are two methods for processing.

The first is to use a mirror spark machine for processing, just to ensure the high precision of the product, it is best to use graphite electrodes for EDM processing, because the loss of graphite electrodes is much smaller than that of ordinary copper electrodes. .

The second is our usual processing method, which is the electroforming mold. The use of electroforming technology can ensure that the mold has good accuracy, but the disadvantage is that the processing time is relatively long, and each cavity must be processed independently. In addition, once minor damage occurs during the production process, it cannot be repaired, and the damaged acupuncture points can only be replaced.

In terms of molds, mold temperature is also a very important parameter for auto parts molds. Auto parts mold processing faces high-end consumers. Now we generally use the concept of high-gloss injection molding and introduce rapid heating and cooling systems. .

Generally speaking, high mold temperature is very helpful to auto parts molds. For example, it can prevent thin-wall filling difficulties and lack of material. It is just that too high mold temperature will bring new problems, that is, cycle lengthening and The problem of shrinkage and deformation after mold opening.

www.yfmould.com

English

English 简体中文

简体中文 Español

Español Deutsche

Deutsche